| Quick Links: |

|

|

| Summary |

HARDOX:

state-of-the-art metallurgical

processes. A unique hardening

process and fanatical control of

specifications.

|

| |

|

|

HARDOX - Selection & Properties |

| |

|

|

|

|

|

High Hardness Increases Wear Life

There is really no secret behind

HARDOX, it is better than any other

steel. Way better. Many times

better. Of course, it involves

state-of-the-art metallurgical

processes. A unique hardening

process and fanatical control of

specifications.

HARDOX wear plate has been developed

to withstand abrasive wear. The

actual wear life depends on the

material in contact with the plate

and the type of wear to which the

subjected.

In the handling of materials, the

equipment is usually subjected to

stress of several types – sliding

and impact wear, also often combined

with heavy deformation. These

different wear conditions would

usually demand materials with

different compositions and different

properties. |

|

|

|

|

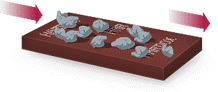

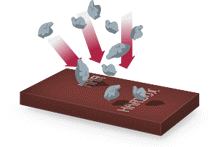

Different Types of Wear

The most common wear types are sliding wear

and impact wear. Abrasive particles trapped

in a narrow gap between two rigid surfaces

causes squeezing wear, which is also a

common wear type. Each material is unique

and contributes differently to the specific

type of abrasive wear damage. |

|

|

|

|

|

|

|

|

SLIDING |

|

IMPACT |

|

SQUEEZING |

|

|

|

In

sliding wear, abrasive material such

as rocks, gravel, concrete, scrap

metal or iron ore are free to slide

and roll with minimum effect on the

steel surface. The right HARDOX

grade will perform excellently and

provide extended service life. |

|

In

impact wear, the aggregate rocks hit

the surface of the wear component at

various angles. Choosing the right

HARDOX grade for the specific

abrasive material will improve

service life considerably. |

|

With

squeezing wear, the improvement in

service life of wear components is

more difficult to quantify. However,

it is easy to determine that HARDOX

plates will improve service life

compared to other steel qualities. |

|

|