HARDOX Provides a Unique Combination of Hardness and Toughness With Extreme Performance and Extended Service Life.

Rocks, sand, coal, minerals, scrap metal, and any other hostile material have a hard time making a lasting impact on HARDOX wear plates. HARDOX’s extreme resistance to wear is a strategic business factor. Extending the service life of your equipment by two, three, five, ten times, or more is like money in the bank.

HARDOX wear plate meets strict demands on wear resistance. The unique combination of consistent and high hardness, high strength, and excellent toughness makes the material well-suited for a wide variety of applications. Throughout the world, HARDOX is now synonymous with high quality, good flatness, and good surface finish.

Although HARDOX plate is 3-4 times harder than ordinary high-strength structural plate, its excellent weldability, formability, and machining properties make the material remarkably easy to work with.

Structural Properties

The most important difference between HARDOX and just ”some hard steel” is the toughness. That is what makes it possible to use it as a structural steel. It can be bent, formed, and welded without losing its properties. Together with the high yield strength, this opens up for lighter designs.

HARDOX Is a Strong Material in Every Respect

Harder, More Wear Resistant

Makes the wear life of the product many times longer.

Extra-High Strength

By using HARDOX, you can make your products simpler and lighter, thus enabling them to carry a higher payload.

Excellent Toughness

Tough even at very low temperatures.

Easy on the Workshop

Good weldability and machinability simplify production and maintenance.

Stock Material Around the World

HARDOX plate is available in more than 40 countries.

Lower Costs - Better Overall Economy

Higher payload, lower maintenance costs, good availability, and a longer useful life combine to offer an improved overall economy.

HARDOX- Availability

Thicker and Thinner Than Ever

Now, we offer wear plates from 0.7 mm to 160 mm. The new dimensions increase the creative area and open up new possibilities where the thickness used to be a limitation.

HARDOX wear plate is available in several hardness levels: HARDOX 400, HARDOX 450, HARDOX 500, HARDOX 550, HARDOX 600, HARDOX Extreme and HARDOX HiTuf. This means that you can always specify a HARDOX steel grade that meets your specific needs.

HARDOX 400 and HARDOX 450 are all-around wear-resistant plates. Due to its high toughness, good bendability, and weldability, the plates can also be used for load-bearing duties in certain applications.

HARDOX 500 is a bendable and weldable abrasion-resistant plate that is used in applications that demand higher wear resistance.

HARDOX 550 is a wear plate with a hardness of 550 Brinell and toughness equal to HARDOX 500. It is intended especially for heavy wear applications and targeted toward users and producers of wear parts using 12% manganese steel castings or 500 Brinell wear plates. The additional 50 Brinell you gain in hardness when upgrading from 500 HBW steels will increase wear life but not at the expense of crack integrity.

HARDOX 600 is a wear plate with a hardness of 600 Brinell. It is indented especially for extreme wear conditions and competes with wear materials like high chromium white alloy castings, Ni-hards, and hard facing. In spite of its extremely high hardness, the steel is weldable and can be machined or cut thermally. For its hardness, the steel also has uniquely high impact strength.

HARDOX Extreme is an abrasion-resistant plate with a typical hardness of 650-700 HBW, intended for applications requiring extremely high abrasion resistance.

HARDOX HiTuf is a wear-resistance plate with extremely high toughness that provides an excellent crack tolerance. HARDOX HiTuf has a hardness of 350 Brinell and is intended for heavy section structural wear parts where extra high demands are applied on the combination of wear and crack resistance.

| PRODUCT | USED FOR | DIMENSIONS | STANDARDS |

|---|---|---|---|

| Hardox HiTuf | Multi-Wear Resistant | T: 40 - 160 mm W: Up to 3350 mm L: Up to 14630 mm | EN 10029 |

| Hardox 400 Sheet | Wear Resistant | T: 2 - 8 mm W: Up to 1860 mm L: Up to 16000 mm. | EN 10051 |

| Hardox 400 Plate | Wear Resistant | T: 4 - 130 mm W: Up to 3350 mm L: Up to 14630 mm | EN 10029 |

| Hardox 450 Sheet | Wear Resistant | T: 2.5 - 8 mm W: Up to 1775 mm L: Up to 16000 mm | EN 10051 |

| Hardox 450 CR Sheet | Wear Resistant | T: 0.7 - 2.1 mm W: Up to 1500 mm L: Up to 8000 mm | EN 10131 |

| Hardox 450 Plate | Wear Resistant | T: 3.2 - 130 mm W: Up to 3350 mm L: Up to 14630 mm | EN 10029 |

| Hardox 500 Sheet | Wear Resistant | T: 3 - 6.5 mm W: Up to 1725 mm L: Up to 16000 mm | EN 10051 |

| Hardox 500 Plate | Wear Resistant | T: 4 - 103 mm W: Up to 3350 mm L: Up to 14630 mm | EN 10029 |

| Hardox 550 | Wear Resistant | T: 8 - 65 mm W: Up to 2900 mm L: Up to 14630 mm | EN 10029 |

| Hardox 600 | Wear Resistant | T: 6 - 65 mm W: Up to 2000 mm L: Up to 14630 mm | EN 10029 |

| Hardox Extreme | Wear Resistant | T: 8 - 19 mm W: Up to 2000 mm L: Up to 14630 mm | EN 10029 |

| Hardox 400 Bar | Wear Resistant Tooling & Engineering | T: 8 - 19 mm W: Up to 2000 mm L: Up to 14630 mm | EN 10029 |

| Hardox 400 Tube | T: 3 - 6 mm D: 30 - 133 mm L: Up to 10000 mm | ||

| Hardox 500 Tube | T: 2 - 6 mm D: 30 - 133 mm L: Up to 10000 mm | ||

| Hardox HiTemp | Wear Resistant | T: 5 - 51 mm W: Up to 3350 mm L: Up to 14630 mm | EN 10029 EN 10163-2 |

Choosing the Right Wear Plate

Hardox wear plate is designed to deliver great performance and a long wear life. You can maximize both by choosing just the right plate for your specific application and requirements.

Hardox steel comes in an impressive range of types, grades, widths, and thicknesses. Where thickness used to be a limitation, SSAB now offers Hardox in thicknesses spanning from 0.7 to 160 mm (0.028 to 6.30"). This — combined with new dimensions and its ability to function as structural steel — allows for even greater creativity and design options.

But regardless of grade or thickness, you've got to have the right balance between hardness, toughness, and workability. Take a look at our guaranteed properties and dimensions below.

| Product

Name |

Hardness Nominal [HBW] | Impact Toughness CVL typ. 20 mm | Bending

properties Transverse

t < 8 mm R/t |

Rel. service

life interval 1 |

CEV/CET

2

Typical 20 mm |

Thickness

[mm] |

| HARDOX HiTuf | 350 | 95 J - 40°C 3 | 0.55/0.36 3 | 3-160 | ||

| HARDOX 400 | 400 | 45 J - 40°C | 2.5 | 1 | 0.43/0.29 | 4-130 4 |

| HARDOX 450 | 450 | 50 J - 40°C | 3.0 | 1.1-4.0 | 0.47/0.34 | 3-130 |

| HARDOX 450 | 450 | 4.0 | 0.39/0.31 8 | 1-2 | ||

| HARDOX 500 | 500 | 37 J - 40°C | 3.5 | 1.3-5.6 | 0.62/0.41 | 4-80 |

| HARDOX 550 | 550 | 30 J - 40°C | 1.5-8.1 | 0.72/0.48 | 10-50 | |

| HARDOX 600 | 600 | 20 J - 40°C | 1.8-12.3 | 0.73/0.55 | 8-50 | |

| HARDOX Extreme | 650-700 | <15 J - 40°C | 2.4-17.9 | 0.84/0.59 | 8-25 |

All plates are produced with AccuRollTechTM precision guarantee or closer.

- Max/min sliding wear by SSAB WearCalc (mild steel 0.2-0,8).

- CEV=C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15;CET=C+(Mn+Mo)10+(Cr+Cu)/20+Ni/40

- 70 mm

- Thicknesses up to 160 mm are available upon request

- Thicknesses up to 120 mm are available upon request.

- Typical values 0.70-2.10 mm

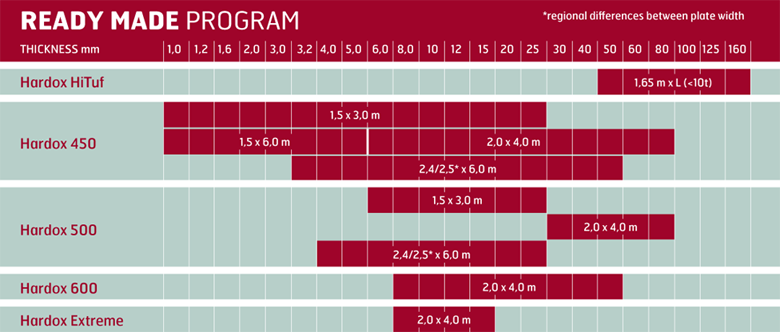

Ready Made Program

To increase availability and delivery precision we have created a ”Ready Made Program” with a selection of our most popular dimensions for each grade of hardness.

Contact A&E Machine Shop, Inc. sales for size and quantity on hand.

HARDOX – Properties

High Hardness Increases Wear Life

There is really no secret behind HARDOX; it is better than any other steel. Way better. Many times, it's better. Of course, it involves state-of-the-art metallurgical processes. A unique hardening process and fanatical control of specifications.

HARDOX wear plate has been developed to withstand abrasive wear. The actual wear life depends on the material in contact with the plate and the type of wear to which it is subjected.

In the handling of materials, the equipment is usually subjected to stress of several types – sliding and impact wear, also often combined with heavy deformation. These different wear conditions would usually demand materials with different compositions and different properties.

Different Types of Wear

The most common wear types are sliding wear and impact wear. Abrasive particles trapped in a narrow gap between two rigid surfaces cause squeezing wear, which is also a common wear type. Each material is unique and contributes differently to the specific type of abrasive wear damage.

HARDOX - Strength/Toughness

High Strength - Higher Payload

Due to its high strength, the HARDOX plate has better dimensional stability and thus sustains a smaller amount of permanent deformation.

A thinner plate can also be used to reduce weight, which then results in a higher payload.

The excellent flatness of the HARDOX plate is also of great importance in the production of tipper bodies.

High Toughness

HARDOX is no ordinary wear plate. Its toughness is very high even under difficult conditions, such as at high rates of strain combined with low temperatures. This makes HARDOX particularly resistant to impact. The properties are the result of an appropriate composition of the steel and an optimized manufacturing process.

HARDOX 450 and ordinary high-strength structural plates have been compared by comprehensive drop tests. The weights varied between 330 and 1,800 lbs and were dropped from heights of up to 10 feet. The moderate deformation of the HARDOX plate is a good measure of its strength.

HARDOX - Working With

Overview of Working with HARDOX

HARDOX can be welded, bent, cut, and machined using run-of-the-mill techniques and tools. You get superior performance from HARDOX without having to invest in special equipment and training.

Preheating

The right preheat and interpass temperature for each welding situation will optimize the result.

Welding

Any conventional welding method can be used to fabricate these steels into any type of weldable steel.

Cutting

HARDOX wear plate can very well be cut using both cold and thermal cutting methods.

Bending

HARDOX is eminently well-suited for cold bending.

Machining

HARDOX can be machined with high-speed steel or cemented carbide tools.

Preheating HARDOX

The right preheat and interpass temperature is important in order to avoid hydrogen cracking. The right preheat and interpass temperature is important in order to avoid hydrogen cracking.

A unique combination of alloying elements optimizes Hardox's mechanical properties. This combination governs the preheat and inter-pass temperature of the steel during welding and can be used to calculate the carbon equivalent value.

Welding HARDOX

Any conventional welding method can be used to fabricate these steels into any type of weldable steel. The information pdf file in the summary column is aimed at simplifying, improving, and boosting the efficiency of the welding process.

It offers good advice on preheat and interpass temperatures, heat input, welding consumables, shielding gas, and a great deal more. We want every user to take advantage of the full benefits of Hardox's unique properties.

Cutting HARDOX

Gas cutting of HARDOX plate is easy. As in all thermal cutting, a heat-affected zone occurs at the cut surface. Thick HARDOX 400/450/500 should be preheated before gas cutting.

For producing smaller parts or to minimize hardness reduction in the zone adjacent to the cut surface, abrasive water-jet cutting or laser cutting may be good alternatives to gas cutting. In abrasive water-jet cutting, which is a cold-working process, the material will lose none of its hardness. In laser cutting, the heat-affected zone is very small.

Press & Roll Bending HARDOX

Purity, flatness, and consistent quality make the HARDOX plate well-suited for press and roll bending. The pdf file in the summary column shows examples of recommended minimum values for free bending of plates of different thicknesses and with different die openings.

As a general rule, a thinner plate can be bent to a smaller radius. The plate can be bent to a smaller radius transverse to the direction of rolling than in the direction of rolling.

Machining HARDOX

HARDOX 400, HARDOX 450, and HARDOX 500 can be machined in all machine tools, using tools with indexable inserts and in a stable, vibration-free set-up.

HARDOX plate can also be machined using a stable radial drilling machine. Rigid HSS-Co drills must be used for drilling. Using appropriate tools, the HARDOX plate can also be spot-faced and counterbored.

Machining a HARDOX plate may produce long chips, particularly when turning. This is due to the high purity of the plate.

HARDOX - Product Facts

HARDOX Product Facts

HARDOX 400, HARDOX 450, and HARDOX 500 have low carbon equivalent values (CEV) in relation to their high hardness and good toughness. This results in good weldability.

Consistent quality, excellent flatness, and surface finish are other characteristics of the plates in the HARDOX family. All HARDOX plates can be delivered blast cleaned and anti-corrosion painted. The quality system at SSAB Oxelösund is certificated to ISO 9001.

For more detailed information on sizes, quality systems, certificates, testing, marking, blast cleaning/painting, etc., please refer to our general product information brochure.

Materials expertise and knowledge of the best way of using plates are important to improve the economy. Our application engineers have accumulated extensive experience with HARDOX in design and production and will be pleased to offer technical advice free of charge at your plant.

This consultancy service is available for the entire chain, from the selection of materials, machining, and welding to surface treatment.

SSAB Oxelösund, which is a member of the SSAB Swedish Steel Group, develops, manufactures, and markets heavy plates.

Learn More

Our specialties are HARDOX wear plate and WELDOX extra high strength structural plate. The whole of our production takes place in an integrated, process-controlled system.

Out of our total annual production of around 500,000 tons, 80—90 percent are exported.

Our HARDOX and WELDOX grades of the plate have become acknowledged concepts on the world market. This is due to a high and uniform standard of quality and a balanced combination of strength, flatness, hardness, formability, and excellent machinability.

HARDOX owes its high hardness and strength and its good toughness properties to quenching with water in our modern roller quenching equipment. Due to this effective process, the content of alloying elements can be minimized, which is beneficial both to the product and to the environment.