| Quick Links: |

|

|

| Summary |

| Duroxite

overlay products from Hardox

Wearparts can add weeks, months,

even years of trouble-free

operations to your most extreme wear

situations. |

| |

|

|

Duroxite - General |

|

|

|

|

|

|

|

Duroxite™-Taking Durability to the Extreme

Duroxite overlay products from

Hardox Wearparts can add weeks,

months, even years of trouble-free

operations to your most extreme wear

situations.

It is comprised of abrasion

resistant materials deposited on top

of mild steel or Hardox® wear plate

to create an extremely wear

resistant compound material. An

optimal carbide composition ensures

homogenous bonding between the base

metal and overlay adding to the high

wear resistance and long service

life of Duroxite.

Duroxite is manufactured by SSAB,

and built on the company’s extensive

metallurgical knowledge in the wear

arena.

Duroxite overlay works especially

well in sliding wear environments

where small and hard materials are

processed such as coal with high

quartz content. It can withstand

different types of wear such as

abrasion, heat, metal-to-metal and

erosion wear. |

|

|

|

|

|

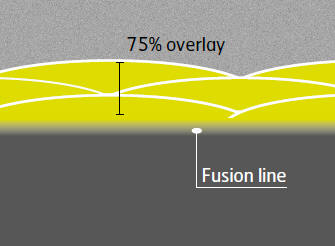

Duroxite

fights wear, guaranteed

Duroxite comes

with guarantees that are unique for the

overlay market. Duroxite overlay products

are delivered with an overlay thickness

guaranteed within +10%.

When you order ¼”

overlay on ¼” base plate, you are guaranteed

an overlay thickness of ¼” within +10%. This

is consistent throughout the plate and from

plate to plate.

Further, consistent wear properties are

guaranteed throughout the plate down to 75%

of the overlay thickness as opposed to just

the surface of the overlay. The remaining

25% of overlay is the transition layer

necessary to maintain good bonding to the

base plate. |

|

|

|

|

|

Duroxite

in fabrication

Duroxite welding

Duroxite is designed to be hard without

giving you a hard time in the workshop. No

special equipment is needed to install

Duroxite. Welding, bolting and stud welding

are the common methods for installing

Duroxite wear parts or overlay plate onto

your equipment. For more information on

installation, see Duroxite brochure.

One of Duroxite’s key benefits is its

excellent formability due to a staggered

cracking pattern on the overlay surface.

This simplifies bending of the plate and

ensures a smooth flow of the processed

materials. |

|

|

|

Proven performance

Duroxite is tough on wear wherever it is

applied. It is the natural choice for

industries active in mining, energy,

quarries, cement production and many other

areas where abrasive materials require

extremely hard surfaces. Here are some

examples from different industries where our

customers have seen extreme benefits from

using Duroxite:

Gold mine, asphalt examples plus the other

applications from the previous brochure

using the format in the brochure with photo

and Industry, Application, Wear part,

Purpose, Type of wear, Benefit. |

|

|